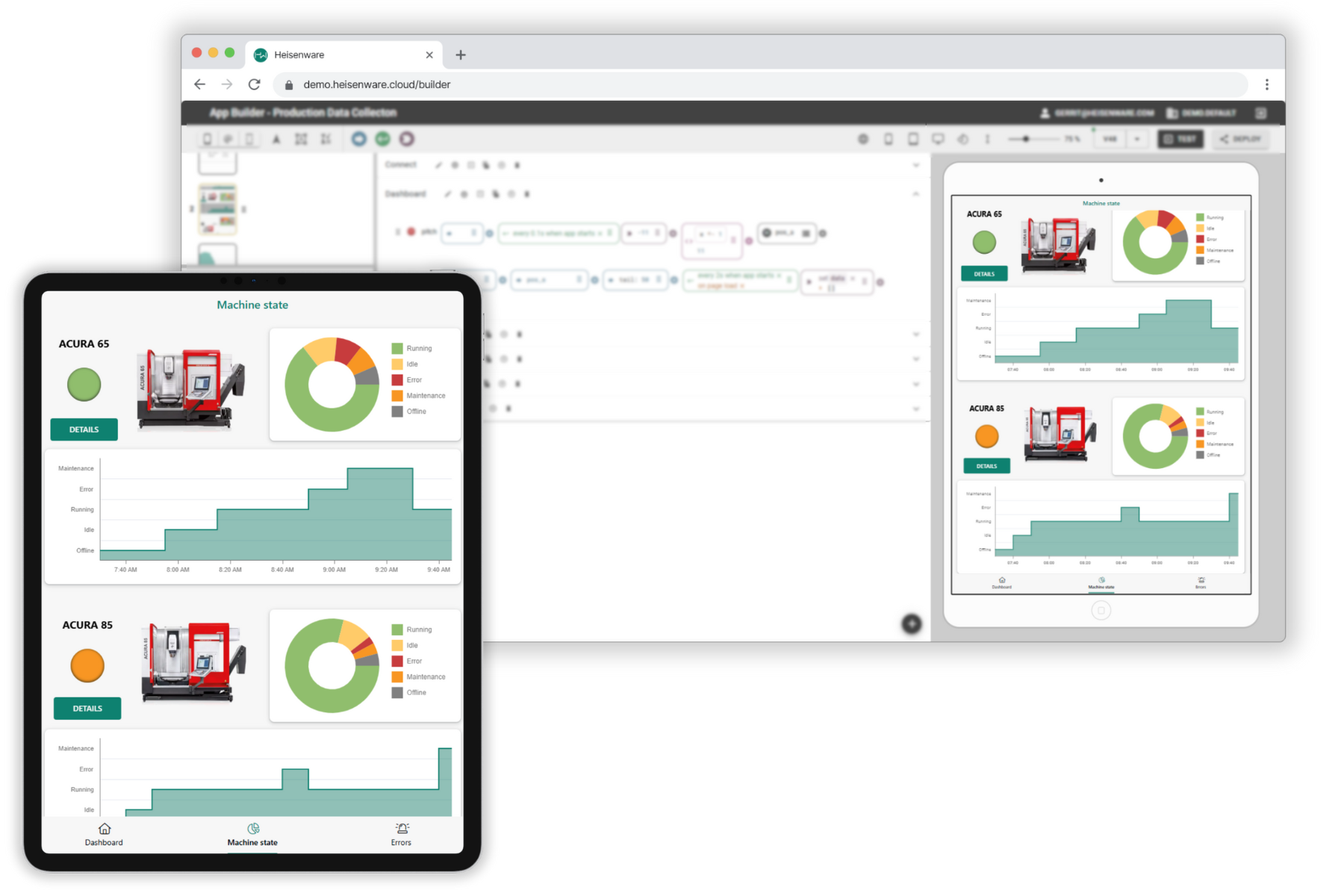

Build production monitoring and workflow automation apps yourself — without code

Stop spending too much or waiting months for custom software from external developers. Build OEE dashboards, systems for machine data acquisition, digital checklists, and more. Run them without the IT hassle.

Why technical teams choose Heisenware

Digitalization the old way:

❌ Node-RED prototypes break in production.

❌ Custom software costs €100k+ and takes months.

❌ Standard software doesn't fit your processes.

Everything you need to build industrial apps yourself

Build apps for every industrial use case

Machine Data Acquisition

Collect live machine signals via OPC UA, S7 or custom protocols. Build real-time dashboards or trigger automated workflows based on your production data.

Production data acquisition

Track quantities, downtimes, and operator input directly on the shopfloor. Combine manual data entry with automated machine feeds for complete visibility.

Condition monitoring

Monitor machine states, temperatures, and process metrics in real time. Set up automatic alerts and trigger maintenance workflows when thresholds are exceeded.

OEE calculation

Build custom dashboards that combine machine and production data. Identify bottlenecks, track performance , and drill down into specific time periods.

Shopfloor dashboards

Create tailored views for operators, team leads, and supervisors. Display live KPIs, production progress, and machine status - updated in real time.

Digital forms

Replace paper checklists with dynamic forms that guide operators through inspections and incident reporting. Include photo capture and QR scanning.

Remote machine monitoring

Build customer portals for machine builders. Collect data from deployed machines and provide insights or predictive maintenance services remotely.

RFID-based inventory tracking

Track materials, parts, and containers with RFID readers. Build mobile-friendly interfaces that show real-time stock levels and location history.

Asset tracking

Know where tools, devices, and machines are at all times. Use RFID, QR codes, or manual check-ins with location-aware mobile forms.

Time tracking

Log time per order, shift, or task with tablet-based interfaces. Track project costs, analyze productivity, or integrate data with your existing systems.

Maintenance management

Let operators create tickets, schedule tasks, and document repairs. Build workflows that escalate issues and track completion status.

ERP & MES integration

Connect legacy systems and modern APIs. Build custom sync processes that move shopfloor data into your ERP, MES, or cloud tools automatically.

Voices from the shopfloor and beyond

With the connector and app from Heisenware, we were quickly able to collect field data, transfer it to the cloud, and thus optimize customer support.

As an integration expert for the shop floor, I am impressed by how easily different systems can be connected using the low-code modules.

Within a very short time, we were able to create a dashboard that displays production data in real-time. Thanks to the existing connectors, we were able to visualize the relevant data without extensive programming knowledge.

The software implemented with Heisenware for RFID-based automatic lending and tracking of tools and keys has greatly simplified our processes. The apps run smoothly on all devices, including smartphone and desktop PC.

What engineers and makers want to know

Where is data stored, and can we self-host Heisenware?

By default, data is stored securely and GDPR-compliant in the EU with our cloud partner Hetzner. If needed, Heisenware can also run fully on-premise or in your own infrastructure.

What makes Heisenware different from other low-code tools?

Heisenware is built for industrial use cases. It handles machine data, protocols like OPC UA or S7, and real-time logic — without the constraints of generic platforms.

How can we connect to assets in our shopfloor network?

The On-Prem Agent lets you deploy connectors in your OT network. It connects securely via MQTTS, allowing you to integrate legacy systems while maintaining network security.

What skills do I need to use Heisenware?

Basic technical understanding is enough — think JSON, databases, and the systems you're connecting. If you can configure Node-RED or work with PLCs, you can build with Heisenware.

What does Heisenware cost?

Plans start at €90/month per app. We also offer professional support, training, and can even build complete apps for you if needed.

Can we try Heisenware?

Yes. Start with a free 30-day trial — no setup needed, just log in and start building. Follow this link to sign up.

.png)