Stop guessing. See your true production data.

Heisenware is the shopfloor app builder that lets your operations team connect to any machine, build live dashboards, and finally see what's really happening. No waiting for IT, no expensive custom projects.

Why your shopfloor is still offline

You see digital potential everywhere, but your reality is a mix of heterogeneous machines and disconnected systems. Instead of live dashboards, you are forced to run critical processes on basic terminals or fragile Excel sheets because you are stuck between two bad options:

Expensive custom projects

External developers are slow, cost a fortune, and rarely understand your specific process.

Bloated standard software

Full MES suites are often too complex, too expensive, and lock you into a rigid workflow that never quite fits.

The journey to full visibility

Start with a simple win and grow from there.

1. See what’s happening (Live Status)

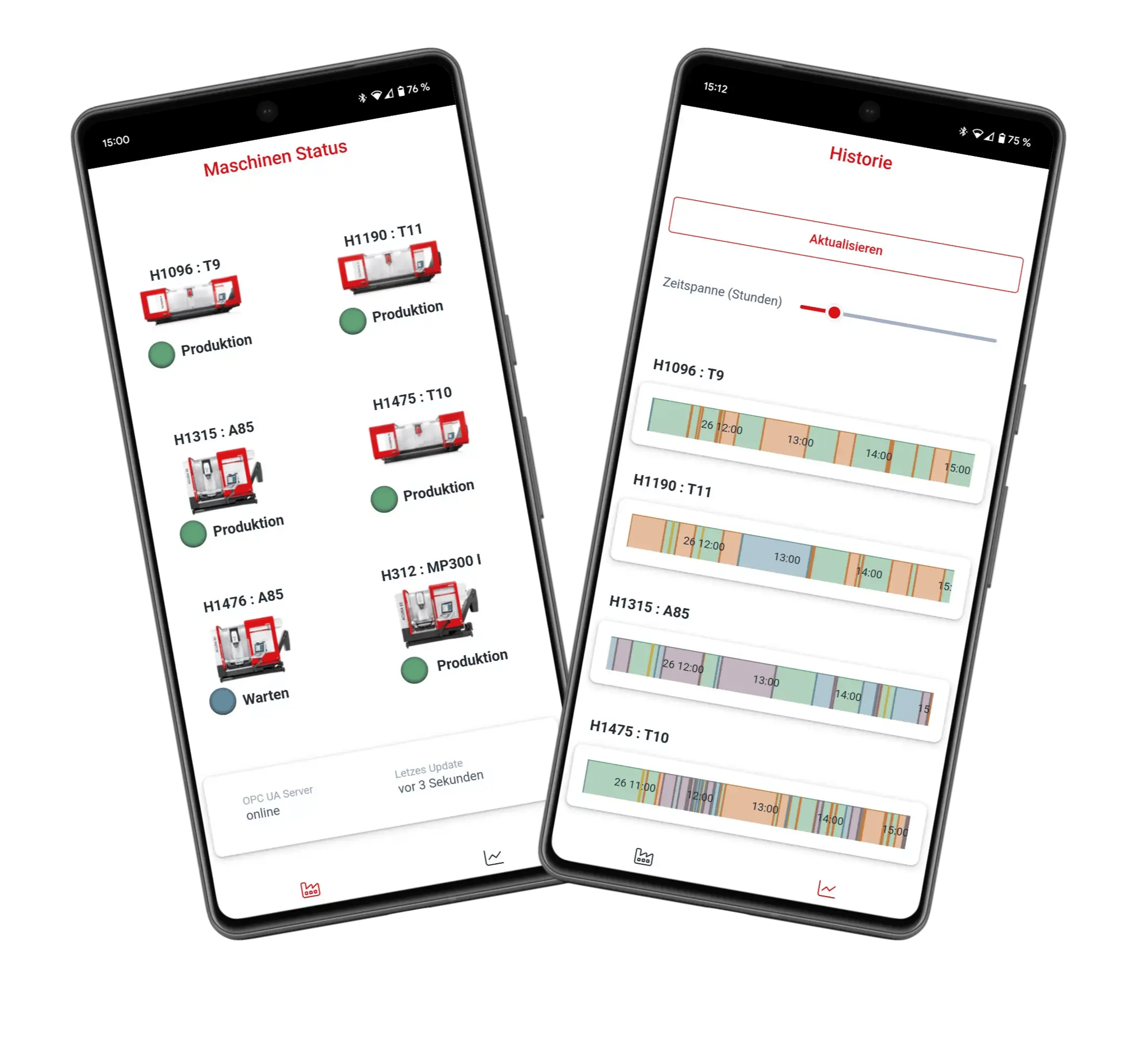

First, see what is up and what is down. Use our connectors to connect to any machine via OPC UA or other industry protocols. In just a few days, you can build a live dashboard that shows you the real-time status of your shopfloor.

2. Know why it stopped (Downtime Reasons)

Now that you see a stop, you need to know why. Use the Heisenware builder to create a simple tablet app for the machine. When it stops, the operator selects a reason. You stop guessing and start knowing.

3. Analyze on order level (ERP Context)

This is where it all comes together. Use our connectors (SQL, CSV, REST) to pull order info from your existing ERP. Now your live data has context. Build dashboards that show real-time "Target vs. Actual" performance for the current shift.

Proven on the factory floor

From complex machine integrations to real-time production dashboards. See how leading manufacturers use Heisenware to create connectivity and build dashboards for their shopfloors.

Within a very short time, we created a dashboard that displays production data in real-time. Thanks to the existing connectors, we visualized the relevant data without extensive programming knowledge.

Case Study: HEDELIUS Maschinenfabrik GmbH

HEDELIUS used Heisenware to connect 11 CNC machines directly to their MES (MPDV Hydra). They automated order feedback and built a live mobile dashboard, eliminating manual data entry entirely.

How we make it possible

This works because we provide the platform for your process experts to become builders.

Connect anything

Our connectors in and on-premise Agents securely talk to PLCs, sensors, SQL databases, CSV files, or your ERP system.

Build visually

If you can build a flowchart, you can build an app. Use our drag-and-drop builder to create logic, dashboards, and HMIs.

Run securely

Your apps are modern PWAs. Access dashboards from a phone, a tablet in the factory, or a desktop. Run it in our secure cloud or 100% on-premise.

A platform for your whole factory

Machine status is just the beginning. Our customers use the same flexible builder to solve dozens of other shopfloor problems.

Digital maintenance

Replace paper clipboards with mobile apps for maintenance schedules and safety checks.

Quality assurance

Digitize QA protocols and capture defect photos directly at the station to ensure compliance.

Asset management

Track the real-time location of tools and equipment to eliminate search times.

Internal logistics

Trigger material replenishment requests (Kanban) instantly with a simple barcode scan.

.webp)