How HEDELIUS automated its MES reporting and gained live machine visibility

HEDELIUS connected its 11 CNC machines to their MPDV Hydra Manufacturing Execution System (MES) using Heisenware, automating order feedback and building a new real-time dashboard. The solution eliminated manual data entry and provided complete production transparency.

At a glance

The challenge

Manual, error-prone data collection from 11 CNC machines (with mixed OPC UA and Heidenhain DNC interfaces). There was no live visibility and no automated data flow to their MPDV Hydra MES, which blocked OEE measurement.

The solution

A two-part system built on Heisenware: a live machine dashboard (PWA) showing real-time status and historical charts, plus a deep, two-way integration with the MPDV MIP platform (as an official MPDV partner).

The result

Full production transparency, less manual work, and a fully automated, error-free data flow. The solution automatically reports completed orders back to the MES, allowing HEDELIUS to measure true OEE inside their MES.

Manual data and a disconnected MES

HEDELIUS Maschinenfabrik runs a high-performance production floor with 11 CNC machining centers. Their core challenge was a lack of automated data flow, which created two major problems:

-

No real-time visibility: Machine data had to be collected manually. This was slow, error-prone, and gave managers no live insight into production status, bottlenecks, or downtime.

-

A disconnected MES: Their powerful MPDV Hydra MES was an "island". The heterogeneous machine landscape—a mix of modern OPC UA and older Heidenhain DNC controls—was not integrated. This meant order data was not sent to machines automatically, and completed orders were not reported back. This "broken loop" made true OEE measurement impossible.

A fully integrated, two-part solution

HEDELIUS used the Heisenware platform to build two distinct applications that solved both problems simultaneously: a live machine dashboard and an automated MES integration.

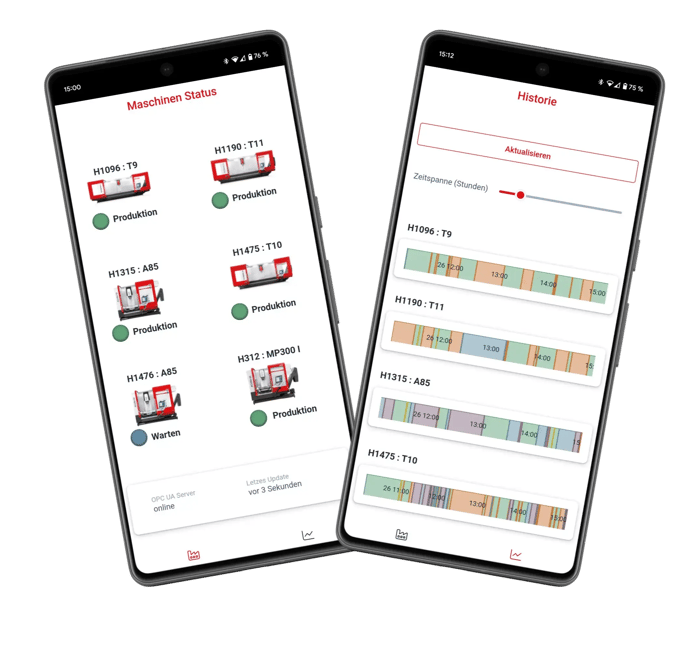

The live dashboard provides real-time, mobile-friendly access (as a PWA) to the machine states and historical performance of all 11 CNC machines.

The automated MES integration creates a seamless, two-way data flow. It sends order data from the MPDV Hydra MES directly to the machine controls and, most importantly, automatically reports completed orders back to the MES, eliminating manual production reporting.

Why it worked: Key platform benefits

HEDELIUS built this custom solution quickly because of the Heisenware platform's unique combination of flexibility and deep integration:

Official MPDV partnership

As an official MPDV partner, Heisenware provided a native MIP Connector. This was the key to enabling the secure, reliable, two-way integration with the Hydra MES.

Flexible connectivity

The platform's native connectors for both OPC UA and Heidenhain DNC made it possible to collect data from their heterogeneous machine park and feed it into one central logic.

All-in-one builder

Heisenware wasn't just a connector. It was the complete toolkit to build the PWA dashboard, the logic to interpret the data, and the integration to the MES, all in one place.

Full transparency and automated processes

The Heisenware solution eliminated manual data collection at the machines, saving time and removing errors. The seamless, two-way integration with the MPDV Hydra MES automated the entire order data flow, making production more flexible and efficient.

HEDELIUS now has full production transparency through its live dashboards. More importantly, by automatically feeding real-time status and completed order data back into the MES, the Heisenware solution provides the clean, reliable data needed to measure true OEE and other critical KPIs.

This project serves as a powerful blueprint for future Industry 4.0 initiatives, both within HEDELIUS and for their customers.