How Gaerte cut asset search by 90%

The Hamburg-based crafts business Ernst Gaerte GmbH & Co. KG transformed its asset management by building a custom RFID check-out solution on the Heisenware platform. The system saves the team hours of search time every week by providing 100% transparency into their tool and key inventory.

At a glance

The challenge

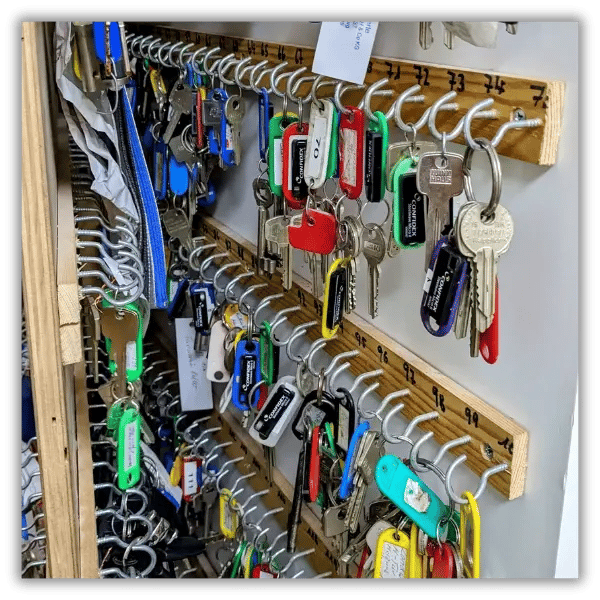

The team was losing valuable time every day. Technicians couldn't find shared tools and keys (300 keys and 100 tools), spending hours on the phone trying to locate them. Manual lists and Excel spreadsheets were impractical and always out-of-date.

The solution

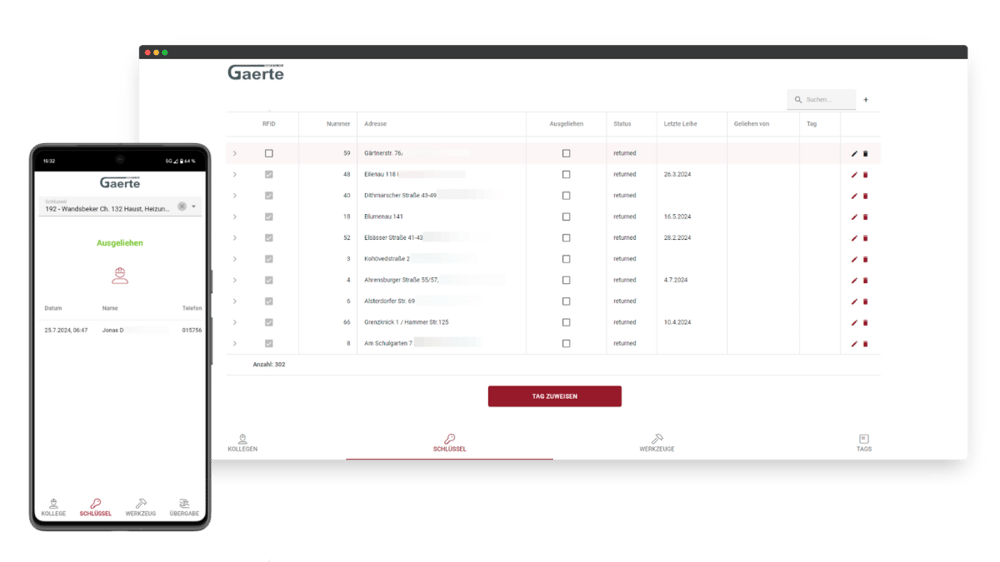

A custom-built asset management system using RFID technology and the Heisenware platform. It includes a semi-automatic check-out station at the warehouse, a mobile app for on-site handovers, and a central dashboard for management, all running on the internal Heisenware database.

The result

The time spent searching for tools and keys was reduced by 90%. The team now has full transparency and knows exactly who has which asset, saving time and eliminating frustration.

A costly, manual workflow

For a busy craft business like Gaerte, time is money. Their manual process for managing hundreds of shared keys and tools was failing. The team was stuck in a costly cycle of searching, relying on outdated manual lists, Excel spreadsheets, or a physical key-board that offered no real tracking.

This lack of transparency made it impossible to quickly locate an asset. Worse, it was impossible to know who had used a tool last or failed to return it.

This reactive model was a drain on the business. It created significant time loss as technicians wasted valuable work hours on phone calls and searching. It also frustrated the skilled technicians, whose time is better spent on-site, not on internal logistics, and it prevented clear planning, as it was often unknown if a critical tool was even available for the next job.

A transparent, automated system

Gaerte used Heisenware to build its own complete "Asset Management System" tailored to their exact workflow.

The solution is a complete, end-to-end system running on the internal Heisenware database:

-

The semi-automatic check-out station: A Zebra RFID antenna is installed at the warehouse exit. When a technician (with an employee tag) walks through carrying a tool (with an asset tag), the antenna scans both automatically. A nearby tablet app displays what was scanned, allowing the technician to confirm the check-out or return with a single click. This prevents accidental scans while still being fast.

-

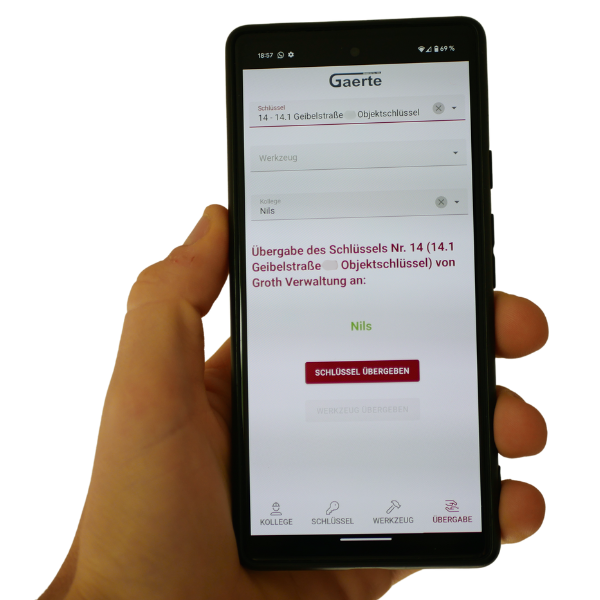

The mobile handover app: This allows technicians to digitally log the transfer of assets (like keys) to a colleague directly on-site, saving a trip back to the warehouse.

-

The overview app: A central dashboard for management and technicians, showing in real-time who has which asset or if it's in the warehouse.

The software implemented with Heisenware for RFID-based, automatic management and tracking of our keys and other assets has greatly simplified our processes. The apps run seamlessly on all devices and save us an enormous amount of time.

Why it worked: Key platform benefits

Gaerte and Heisenware built this solution in a fraction of the time of custom development, thanks to two key platform features.

Seamless hardware integration

The Heisenware Agent could talk directly to the Zebra RFID antennas. The platform translated the raw, simultaneous hardware scans into clean, usable logic (e.g., "this person took this tool").

The visual builder

Gaerte wasn't locked into one app. They had the flexibility to build four different apps for each specific use case (admin, tablet, mobile, dashboard), all running on the same data, perfectly matching their real-world process.

Time saved and a clear next step

The new system's impact was immediate and clear: the time spent searching for tools and keys was reduced by 90%.

This transformed a frustrating, manual process into an efficient, transparent workflow that the entire team relies on. The new transparency eliminated daily frustration and freed up technicians to focus on billable work.

With this success, Gaerte is already planning the next logical expansion: building a new app to replace their analog process for integrating and managing external companies who also borrow keys.