Digital Maintenance Management: From Chaos to Controlled Workflow

When a Quick Shout Isn’t Enough

“Machine 3 is down!” – a sentence that often triggers a chain of uncoordinated actions. Who is responsible? Has the issue already been reported? Is the spare part available? In many manufacturing plants, maintenance still resembles a reactive firefighting unit. Problems are reported verbally or scribbled on sticky notes, leading to information loss, long downtimes, and frustrated employees.

Digital maintenance management replaces this chaos with a clear, transparent, and traceable process. At the heart of such a solution lies a simple digital ticketing system. It ensures that no incident gets lost and that everyone knows exactly what needs to be done. This guide shows you how to use a low-code platform to build your own lean maintenance tool—massively increasing the efficiency and reliability of your production.

The Pain Points of Analog Maintenance

Traditional paper-based maintenance is a constant source of problems:

-

Information loss: Verbal agreements are forgotten, notes get lost. There’s no central, reliable source of information on machine conditions.

-

Long response and downtime: By the time an issue reaches the right person and all details are gathered, valuable production time is lost.

-

Lack of transparency: No one has a full overview of the current status of all open issues. Priorities are set by gut feeling rather than urgency.

-

No knowledge database: Valuable problem-solving know-how often exists only in the head of a single employee. If that person leaves, the knowledge is gone—making knowledge-based maintenance impossible.

The Solution: A Simple Digital Ticketing System

Imagine an app available on every production tablet. With this app—built on your low-code platform—reporting and handling issues becomes effortless.

-

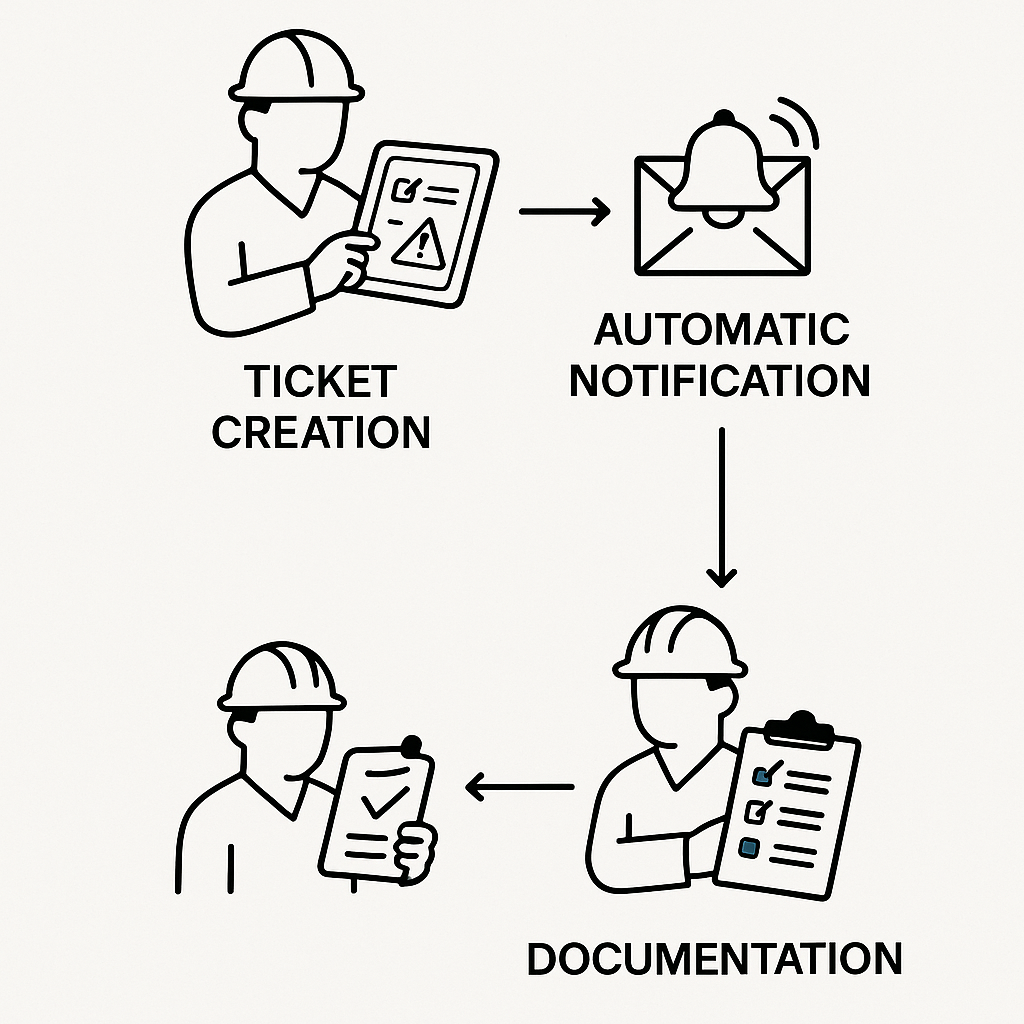

Easy ticket creation by operators:

-

Select the machine via scan or from a list.

-

Choose the problem from a predefined list (e.g., “Mechanical issue,” “Electrical fault”).

-

Add a photo or short video of the problem.

-

-

Automatic notification and assignment:

-

As soon as a ticket is created, the maintenance team (or a specific person) automatically receives an email or push notification.

-

The ticket instantly appears in a central dashboard.

-

-

Transparent processing and documentation:

-

The technician updates the ticket status (e.g., “In progress,” “Waiting for spare part,” “Completed”).

-

Actions taken and time spent are documented directly in the ticket.

-

Every step is logged with a timestamp, creating a complete record.

-

From Ticket to Knowledge Database

Every resolved ticket automatically becomes a valuable entry in your digital knowledge database. If the same problem arises again, any technician can check how it was solved last time. This not only speeds up future repairs but also supports onboarding new employees.

Your Low-Code Platform: The Fastest Path to a Custom Maintenance Tool

Instead of implementing a complex and expensive CMMS (Computerized Maintenance Management System) that includes 80% features you’ll never use, you can build your own lean solution with low-code.

-

Perfectly tailored to your processes: Define fields, statuses, and workflows exactly the way they fit your team.

-

Integrate what you need: Connect your ticketing system directly with your spare parts inventory to check availability, or with machine data collection to trigger tickets automatically for recurring fault patterns.

-

Start small, scale fast: Begin with a simple ticketing system for one department. Once it proves effective, roll it out across the entire plant and gradually add features like maintenance scheduling or managing external service providers.

Conclusion: Turn Maintenance into a Strategic Advantage

Digital maintenance management is more than just a tool for fixing breakdowns. It’s a system that creates transparency, boosts efficiency, and secures valuable knowledge. You’ll reduce unplanned downtime, optimize resource usage, and build a calmer, more controlled work environment. With a flexible low-code platform, you lay the foundation for proactive, data-driven maintenance that actively contributes to your company’s value creation.