Digital Forms & Work Instructions: The Guide to a Paperless Factory

Declare War on Paper Chaos

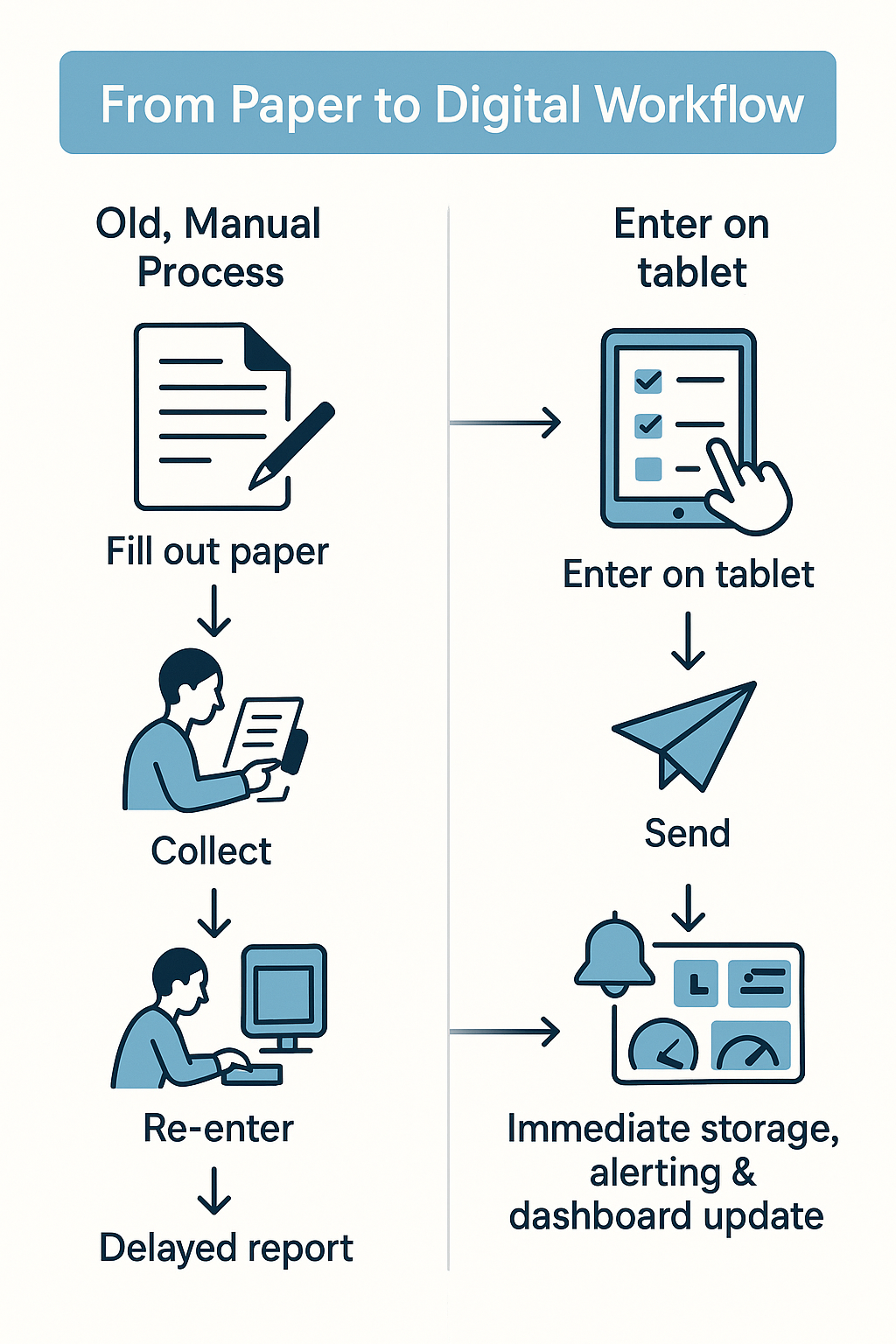

Let's take an honest walk through your production facility: how many clipboards, printed Excel sheets, and outdated binders with work instructions would you find? Paper is patient, but in modern manufacturing, it's primarily one thing: an efficiency killer. It leads to errors, slows down processes, and creates information silos. Every signature on a dusty checklist is an admission that valuable data is disappearing into an analog black hole.

The digital transformation of your shop floor doesn't start with complex AI projects; it starts with eliminating paper. Digital forms and dynamic work instructions are the first, crucial step toward transparent, error-free, and agile production. This guide shows you how to eliminate paper-based processes and thereby lay the foundation for operational excellence.

The Problem with Paper: More Than Just Messy

The disadvantages of paper-based processes go far beyond lost slips of paper:

-

Lack of Data Integrity: Handwritten entries are often illegible, incomplete, or simply incorrect. A study by Forrester highlights the immense costs businesses incur due to poor data quality. This flawed data becomes the basis for critical decisions.

-

No Real-Time Transparency: Information is only available after someone collects the papers and manually enters them into a system. Problems are detected hours or days too late.

-

Lack of Process Reliability: It's difficult to ensure that every employee is always using the most current version of a work instruction. Outdated instructions lead to quality defects and rework.

-

Inefficient Workflows: A paper form cannot automatically send an email, create a maintenance ticket, or update inventory levels. Every process step requires a manual handoff.

The Solution: Dynamic Digital Forms

Imagine a digital form on a tablet that does more than just display fields. A low-code platform allows you to create intelligent, dynamic forms that actively guide your employees through the process.

-

Guided Workflows: The form only shows the fields relevant to the specific context. Based on an input (e.g., "Defect found"), new fields can dynamically appear (e.g., "Take photo of damage," "Select defect category").

-

Integrated Data Capture: Use the tablet's camera to document damages, or use barcode and QR code scanners to uniquely identify materials or workpieces. This eliminates typos when entering long serial numbers.

-

Real-Time Validation: Define mandatory fields and plausibility checks. The system can immediately issue a warning if a measurement is out of tolerance or an entry is missing.

-

Automated Processing: As soon as a form is submitted, a workflow starts in the background. The data is saved in a central database, a notification is sent to the quality manager, and the results are visualized live on a dashboard.

Use Cases That Deliver Immediate Value

-

Digital Quality Checklists: Guide workers through the end-of-line quality inspection, complete with photo documentation and direct connection to the ERP system for good/bad part reporting.

-

Autonomous Maintenance (TPM) Checklists: Provide your machine operators with a simple app to document daily or weekly maintenance tasks (e.g., "Check lubrication," "Clean filter").

-

Digital Shift Handover: Ensure a seamless flow of information between shifts. Capture open points, special incidents, and production KPIs in a structured way, so the next shift is immediately up to speed.

-

Safety and 5S Audits: Conduct safety walks digitally. Document hazards with photos and assign corrective actions directly to the responsible individuals.

Your Low-Code Platform: The Fastest Way to a Paperless Factory

Instead of waiting for rigid standard software that doesn't 100% match your processes, a low-code platform allows you to become the designer yourself.

-

Build Apps in Hours, Not Months: Thanks to visual drag-and-drop editors, you can create forms and simple apps tailored exactly to your needs, without programming knowledge.

-

Involve Your Employees: The people who know the processes best are the ones who perform them daily. Empower your supervisors and experienced workers to participate in designing the digital forms. This builds acceptance and leads to better results.

-

Iterate and Improve: A digital process is never static. You can adapt and improve your forms and workflows with just a few clicks whenever requirements change.

Conclusion: More Than Just Saving Paper

Switching to digital forms and work instructions is the starting point for a profound optimization of your manufacturing. You not only create order but also build a reliable, complete, real-time database. You increase process reliability, reduce errors, and provide your employees with intelligent tools. Stop burying data in file folders and start using it.