Accurate Post-Calculation: Why Your Paper-Based Time Tracking Is Costing You Money

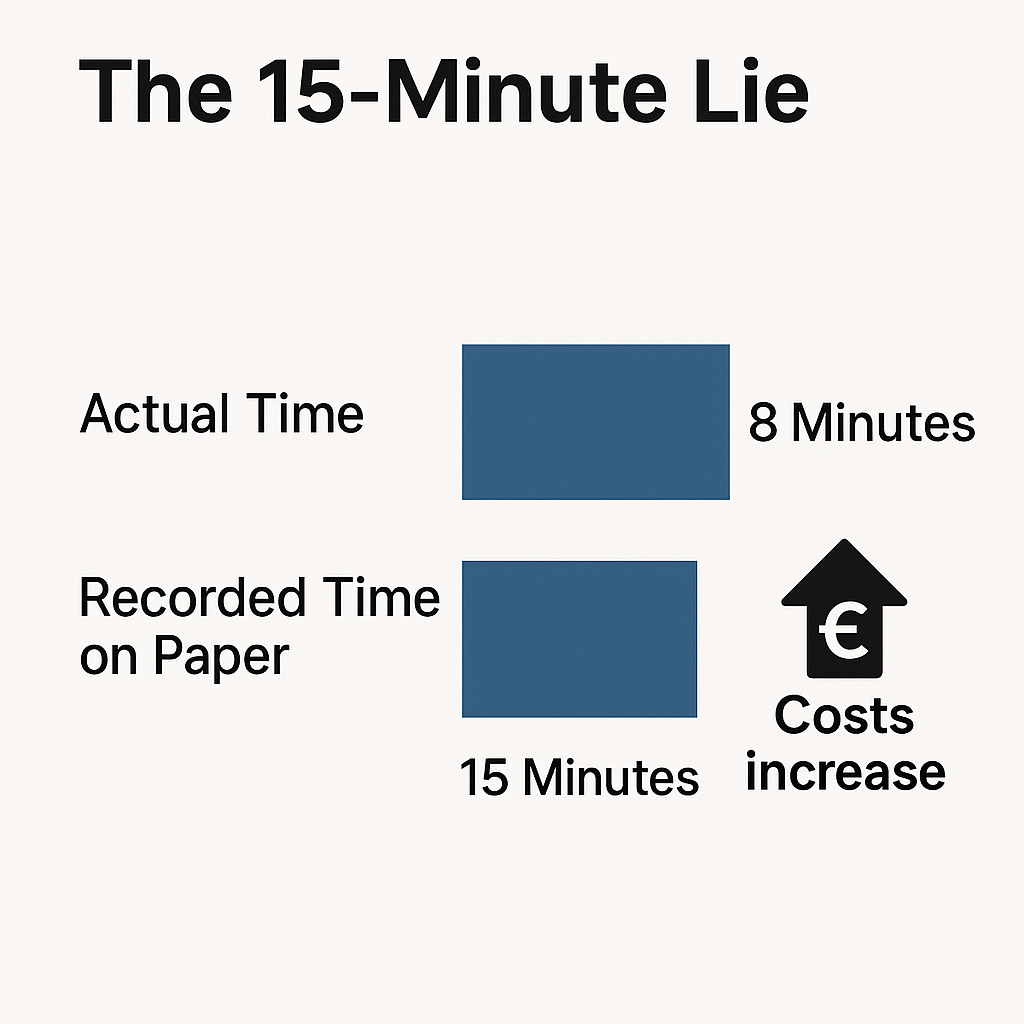

The 15-Minute Lie and Its Consequences

Let’s be honest: How accurate is time tracking really in your production? Employees often rely on memory and jot down rough estimates at the end of the day. Eight minutes turn into fifteen, setup times are forgotten, and short interruptions are left out entirely. These inaccuracies are not only annoying—they’re a massive problem for your profitability.

Accurate post-calculation is the foundation of every successful manufacturing business. If you don’t know exactly how much labor time goes into an order, your pricing, capacity planning, and productivity assessment are pure guesswork. The good news: switching to digital, order-based time tracking is easier than you think.

The Problems with Manual Time Tracking

-

Inaccurate post-calculation: Labor costs are one of the biggest cost factors in manufacturing. If your recorded times are wrong, you don’t know which orders are profitable and where you’re losing money.

-

Low productivity transparency: You can’t analyze why an order took longer than planned. Was it the employee, the material, or a disruption? Without accurate data, you’re left in the dark.

-

High administrative effort: Collecting, typing in, and evaluating timesheets ties up valuable admin resources that could be used more effectively.

-

Lack of fairness: Blanket time tracking makes it impossible to fairly assess performance and reward productive employees.

The Solution: A Simple Time Tracking App on a Tablet

Imagine a simple tablet at every workstation. With an app you’ve built on your low-code platform, employees can record their times in just a few clicks:

-

Select order: The employee scans the QR code on the production order or selects it from a list.

-

Start/Stop/Pause: Large, easy-to-use buttons record work start, breaks, and task completion—down to the second.

-

Assign activity: Employees can specify whether they’re setting up, producing, or troubleshooting.

-

Automatic transfer: The data is instantly sent to your central database, ready for evaluation.

The Immediate Benefits of Digital Time Tracking

-

Reliable post-calculation: You know the exact labor costs for each order and can set prices and margins based on facts.

-

True productivity analysis: Compare planned vs. actual times per order. Identify which products or processes are particularly demanding and where optimization potential lies.

-

Reduced admin workload: Digital tracking eliminates manual steps. Data is instantly available for payroll and controlling.

-

Fair performance evaluation: You gain an objective basis for evaluating teams and employees, enabling targeted training.

Conclusion: Stop Guessing

Manual time tracking is an expensive relic of the past. It costs you money, transparency, and optimization potential. With a simple app built on your low-code platform, you can take the decisive step toward data-driven production management. You create a fair, transparent, and highly efficient work environment—and finally make business decisions based on real numbers.